|

Importance of Pickling & Passivation Stainless Steel

In addition to ensuring corrosion resistance, the Pickling & Passivation process removes free ions from the SS surface during manufacturing & fabrication. Contaminants such as these lead to corrosion, eventually resulting in component failure if not removed.

A large part of SS's corrosion resistance is due to its 13 percent chromium content. Chromium and oxygen form chromic oxide, an important chemical barrier that protects SS surfaces from corrosion. A passive layer is generally regenerated after abrasion. There is always a risk of mechanical damage to the top layer of components, including the following:

- Stainless steel layers at the top are modified structurally

- Development of in-built stress

- Ferritic contamination

- Reduced chromium content on top of the SS

When annealing and welding SS surfaces become scaly and discolored. As a result of this, Stainless Steel is less valuable as a result of appearance and lower corrosion resistance. The presence of these contaminants causes corrosion stain to mount on insufficiently passivated steel due to the failure of the preventive layer of chromium to form.

A properly pickled and passivated SS seam and weld offers the following benefits:

- An extremely smooth, metallically pure and discolouration-free surface

- Good and decorative metallic appearance

- Corrosion resistance improved in stainless steel components

- Passive chromium oxide layer optimally restored

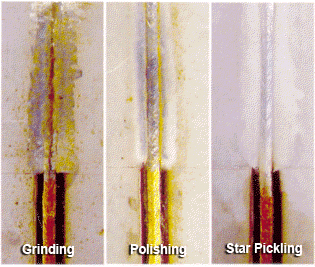

How is Pickling Done?

Pickling is either done in a pickling bath or on the metal surface of the components that require pickling, depending on their size and shape. Several minutes to few hours are needed at a room temperature to let it work properly, and then it's rinsed thoroughly with water.

Acid blends with the active chemicals result in removal of components' surface layers of 1-3 microns.

In the process, discolorations, oxide scales, surface contaminations, and ferrites are removed.

After rinsing, proper passive film formation is seen when exposed to the breeze.

|

|